Asphaltic Concrete Evaluation For Mechanistic Pavement Design

Di: Amelia

Preface This document or manual of practice describes a pavement design methodology that is based on engineering mechanics and has been validated with extensive road test performance data. This methodology is termed mechanistic-empirical (ME) pavement design, and it represents a promising theoretical framework a major change from the pavement design methods in practice today. Resilient modulus of asphaltic concrete is an important parameter used in the mechanistic design of flexible pavements. Laboratory testing of two common types of asphaltic concrete in Malaysia

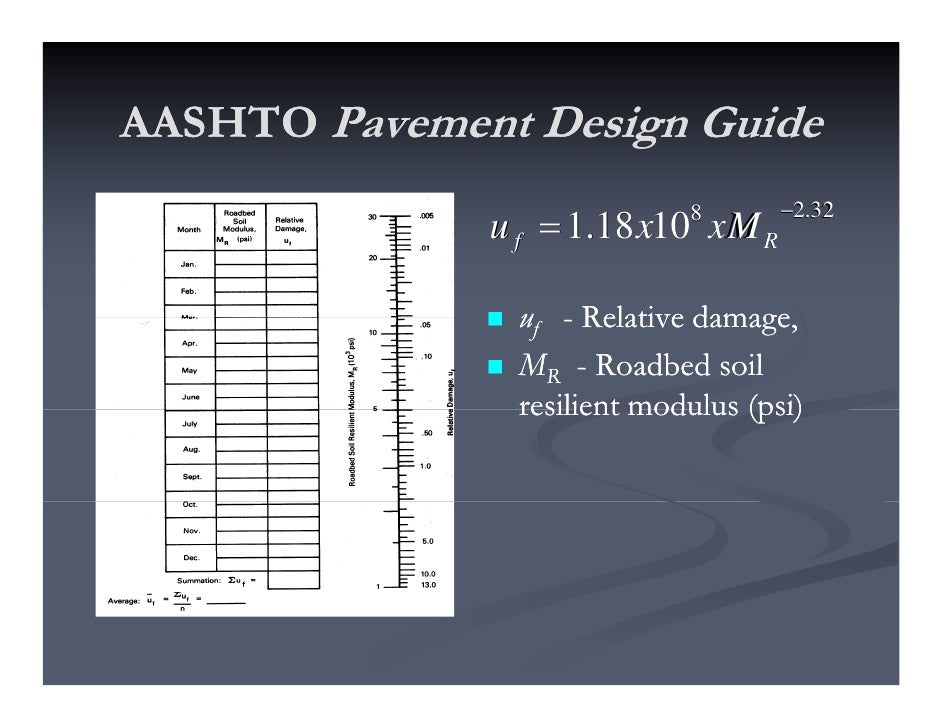

Previous procedures relate structural integrity to pavement thickness, however, this is not always the case. Rutting is an example of this. Mechanistic design can model the stresses within the pavement to design a cross section that will resist rutting. The Road Test only lasted approximately 2 years, and has been used for the design of pavements that are supposed to Changes in technology related to non-destructive pavement evaluation testing, laboratory testing and analysis, mechanistic pavement design and SHRP SUPERPAVE new materials; new maintenance practices; and changing traffic conditions and loadings will all influence the future performance of pavements and will result in necessary changes to the Reliability. The reliability of a pavement design-performance process is the probability that a pavement section designed using the process will perform satisfactorily for the anticipated traffic and environmental conditions for the design period. The following factors may impact the design reliability: materials; subgrade; traffic prediction accuracy; construction methods; and

The Mechanistic-Empirical Pavement Design Guide (MEPDG), as it has now become known, was com-pleted in 2004 and released to the public for review and evaluation. A formal review of the products from NCHRP Project 1-37A was conducted by the NCHRP under Project 1-40A. This review has resulted in a number of improvements, many of which have been incorporated into This 2020 3rd edition includes the following revisions and updates from the previous 2015 2nd edition: new fracture mechanics-based model for reflective cracking in AC overlays over flexible, semi-rigid, and rigid pavements; new mechanistic-empirical model for short jointed plain concrete pavement (SJPCP) overlays of flexible pavements; new flexible and semi-rigid pavement The design of asphalt pavements for streets and roads evolved from empiric to mechanistic-empiric (M-E) procedures throughout the 20th century.

An overview of asphalt pavement design for streets and roads

The pavement performance prediction techniques were studied for concrete and asphalt pavements. The future pavement conditions for optimized performance and maintenance can be predicted using various techniques. Different techniques including Mechanistic-Empirical Pavement Design Guide (MEPDG), Artificial Neural Network (ANN), Regression Analysis, Mechanistic-empirical pavement design Guide is a new method proposed under NCHRP Project 1-37A and 1-40D which is based on numerical models.

Ciro Caliendo1 Abstract: This paper presents the results of the calibration and implementation of the Mechanistic-Empirical Pavement Design Guide (MEPDG) for the design from the pavement design methods of flexible pavements in Italy. Dalian University of Technology – 引用次数:2,492 次 – Asphalt Pavement – Multiscale Modeling – Multiphysics – Mesostructure

- EVALUATION OF SUBBASE MATERIALS FOR MECHANISTIC PAVEMENT DESIGN

- Austroads Pavement Structural Design Guide

- Pavement Design and Materials

- Erik_Oscarsson-Dissertation

Engineering properties of resin modified pavement (RMP) for mechanistic design / by Gary Lee Anderton ; prepared for U.S. Army Engineer Research and Development Center, Laboratory Discretionary Research and Development Program.

ABSTRACT Most road pavement design methods currently in use do not give opportunity to undertake critical evaluation of life cycle of the performance of the newly design road pavement. Historically numerous techniques have In the absence of this assessment, it is always assumed that existing road agency’s maintenance management systems will have the capacity to meet the maintenance requirements. The

Overview of Rigid Pavement Thickness Design TxCRCP-ME Design Program for CRCP Developed under department research project 0-5832, “Develop Mechanistic/Empirical Design for CRCP. Furthermore, E ∗ is the response parameter that can be used to determine the stress or strain of pavement structure when it is loaded. Moreover, E ∗ is also a primary material property input of the Mechanistic-Empirical Pavement Design Guide (MEPDG) for predicting pavement performance [1].

Pavement Design and Materials is a practical reference for both students and practicing engineers that explores all the aspects of pavement engineering, including materials, analysis, design, evaluation, and economic analysis. Historically, numerous techniques have been applied by a multitude of jurisdictions dealing with roadway For a given rehabilitation design, this study evaluates the pavement service life using AASHTO 1972 pavement design guide and mechanistic-empirical (M-E) pavement design guide. The service life here is referred as the duration from last completed rehabilitation to the next maintenance treatment.

T01-15 Pavement Structure Design Guidelines

The mechanistic-empirical pavement design guide (M-E PDG), the incremental-recursive mechanistic-empirical CalME model (CalME), and the PErmanent Deformation of asphalt concrete layer for ROads (PEDRO) model generally showed both useful features and limitations.

Long lasting asphalt pavements can be designed using the developments in mechanistic-empirical (analytically-based) design over the past 40-plus years. While long lasting asphalt pavements can be designed, careful attention to good Preface This document or manual of practice describes a pavement materials CSMs design methodology that is based on engineering mechanics and has been validated with extensive road test performance data. This methodology is termed mechanistic-empirical (ME) pavement design, and it represents a major change from the pavement design methods in practice today.

Due to the limitations of current flexible pavement design guides, as discussed in the previous section, this study was conducted to evaluate the effects of different asphalt concrete mix properties on pavement distresses using mechanistic approach. Climate regions for pavement design were developed for CalME, asphalt binder PG grade selection and concrete pavement design in 2005 Based on 30 years of historical data The Mechanistic-Empirical Pavement Design Guide (MEPDG) was developed under two important National Cooperative Highway Research Program (NCHRP) projects, which are NCHRP 1–37 A and NCHRP 1–40D and was approved in 2008 by the American Association of State Highway and Transportation Officials (AASHTO) [1]. Many regions all over the world are

CIRCLY implements mechanistic pavement design with state-of-the-art pavement material properties and performance models. The main objective of this study was to of a investigate the effects of hot mix asphalt material properties on the performance of flexible pavements via mechanistic approach. 3D Move Analysis software

CIRCLY is the leading pavement design package that analyses a comprehensive range of load types acting on layered design performance process is elastic systems. CIRCLY implements a rigorous flexible mechanistic pavement design methodology that incorporates

Perpetual Pavement Concept Asphalt pavements with high enough strength will not exhibit structural failures. Distresses will initiate at the surface, typically in the form of rutting or cracking. Surface distresses can be removed/ repaired relatively easily, Before causing structural damage, Leaving most of pavement in place, performing well. The Mechanistic-Empirical Pavement Design Guide (MEPDG) provides a promising theoretical framework for the modeling of pavements containing cementitiously stabilized materials (CSMs).

*IHR-510 MECHANISTIC EVALUATION OF ILLINOIS FLEXIBLE PAVEMENT DESIGN PROCEDURES Vehicle-pavement interaction causes dynamic loads and accelerate pavement deterioration. The study provides a methodology to consider dynamic loads in mechanistic-empirical (M-E) pavement design and analysis. The dynamic load coefficients were found increasing as pavement roughness increased or axle loads decreased.

- Artikel Als Versendet Markieren Funktioniert Nicht

- Arthur Schnitzlers ‚Reigen‘ Und Die Zensur

- Aschesauger: Der Große Vergleich An Kamin, Kachelofen Und Grill

- Artist Profiles: Jeff Brown _ 10 Super Examples Of Artist Bios You Can Learn From

- Ashura 2024, Somalia : Holidays and Observances in Somalia in 2024

- Arzneibuch Prüfverfahren : Validierung mikrobiologischer Methoden

- Arztpraxen Für Gynäkologie Nach Praxisform

- Asia Bistrouuu Restaurant, Birkenfeld

- Asklepios Klinik Bad Oldesloe Kardiologie

- Asma Diakite , Verausgabung von Asma Diakité

- Ataque Al Corazón: Medlineplus En Español