Manufacturing Of Forging Dies, Forging Dies Production Process

Di: Amelia

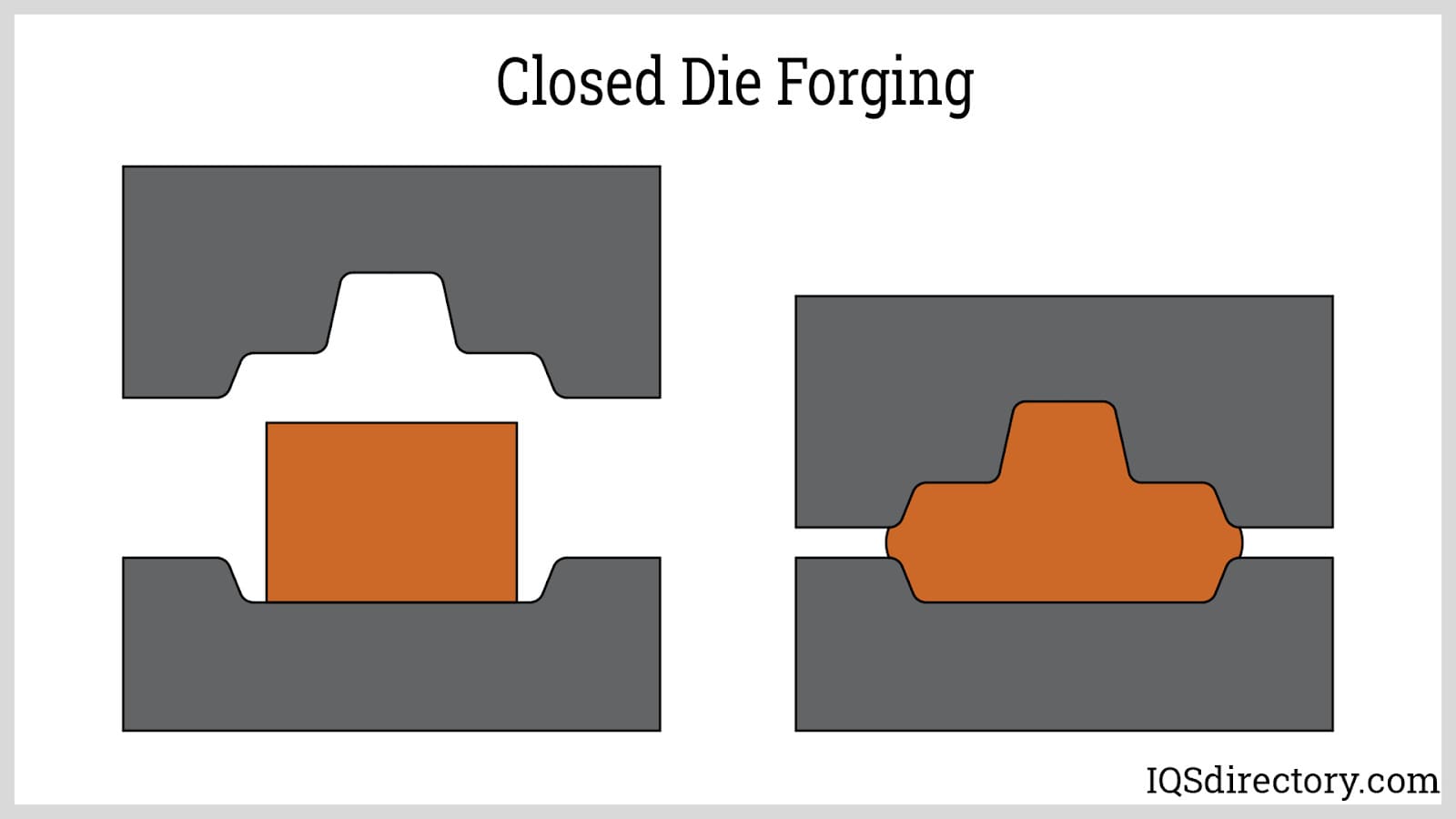

Advantages: High Precision: Closed die forging offers excellent dimensional accuracy and detailed shapes. The process can produce parts with complex geometries and tight tolerances. Production Efficiency: Once the dies are created, closed die forging can be automated, allowing for the mass production of parts with consistent quality. Roll forging In this process, the bar stock is reduced in cross-section or undergoes change in cross-section when it is passed through apair of grooved rolls made of die steel. This process serves as the initial processing step for forging of parts such asconnecting rod, crank shaft etc. FORGING PROCESSES Forging is the process of mechanical working of metals. In this process, the desired shape is obtained by the application of a compressive force. In hot forging, the metal is heated above the recrystallization temperature. Then, it is compressed and squeezed to the required shape by using a hammer or press tool. 1. Steps in Forging Operation The forging

Bot VerificationVerifying that you are not a robot The Process of „Open Die Forging“ Involves Forcing Metal Between Two Flat or Curved Dies to Shape It Into Parts. A Heated Piece of Metal is Hammered or Squeezed Between Two Flat Dies During the Open Die Forging Process, Which Shapes Metal. 5CrMnMo is a cost-effective hot-working tool steel that is commonly used in the manufacture of hot forging dies. Wear is the principal mode of failure for these material dies. Studying its high-temperature wear mechanisms and building a high-temperature wear model can assist to reduce wear and extend the service life of related dies.

In the world of manufacturing, choosing the right process for creating metal parts can significantly impact the final product’s performance, cost, and durability. Die casting and forging are two prominent methods, each with unique advantages and limitations. But how do they really stack up against each other? Understanding the core differences between these two Classification of Forging Processes Based on Arrangement of Dies: Open Die Forging: Flat dies of simple shape are used. Fig. Open Die Forging Features of open die forging: Repeated impact blows are given on the work Less dimensional accuracy Suitable only for simple shapes of work Requires more skill of the operator

Principles and Applications of Open vs. Closed Die Forging

Considering the most common cases, isothermal forging is done in vacuum conditions or highly restricted atmosphere on super alloys to restrict it from getting through the process of oxidation. 5. Seamless Rolled Ring Forging: ( Types of Forging Process ) Same as the other die forging processes, rolled ring forging compresses dies to shape of desired/required material. However, Die forging is defined as a metal shaping process involving the use of dies, where metal is deformed under high pressure to create specific geometries, typically resulting in enhanced mechanical properties compared to machining. AI generated definition based on: Comprehensive Materials Processing, 2014

Four types of forging manufacturing processes are commonly used to shape metal parts. These metal forging processes include impression die forging (closed die), open die forging, cold forging, used in the production of and seamless rolled ring forging. Using localized compressive forces, metal forgings provide a highly effective way to create various parts for all applications. Great Lakes Forge is a proud

2.4.1 Open Die Forging It is the simplest forging process which is quite flexible but not suitable for large scale production. The operation is carried out between two flat dies or dies of very simple hot forging shape, figures 6a & 7. The process of open die forging is carried out in large hydraulic presses or power hammer. Since in open die forging the workpiece is usually larger than the tool, at any

A wide range of metals can be forged. Hot forging is one of the most conventional metal forming processes used in the production of critical parts in the manufacturing of automobiles and industrial machine components. The forging die is a crucial tool in the die forging process, which is a key factor in the production process. CAD/CAM Design Before manufacturing of forging dies, we can not start the production process directly. Firstly, engineer need to know how to design the forging dies following the drawing of a new forging part. Design of forgings dies depends on the processing steps, nature of workpiece material, flow stress, working temperature, ect. All these factors need to be considered. Then

So, in order to achieve the exact dimensions of the final product, the dies are designed undersized or alternatively, the product may proceed to a machining manufacturing process, in order to be formed in the desired dimensions (ASM, 1993).

Forging is a deformation process in which the work is compressed between two dies, using either impact or gradual pressure to form the part. TRUE or FALSE Forging, a manufacturing process, involves shaping and forming metal using compressive force. There are six types: hot, cold, drop, press, upset, and roll forging. Elmet Technologies specializes in engineering and manufacturing isothermal forging dies with advanced performance characteristics. Our extensive material capabilities includes the customization of alloys to improve the overall forging process, therefore resulting in higher quality end products. We offer complete control over material integrity, quality, and performance.

Forming Processes: Forging

Forging is a manufacturing process that shapes metal by applying compressive forces, often using dies and hammers. This technique enables you to create components with superior strength and durability compared to other Microstructure Changes: While forming induces on the plastic deformation, the changes in the metal’s microstructure are less pronounced compared to forging. Visual Diagrams Illustrating Metal Deformation in Each Process In forging, the metal is heated to a suitable temperature and placed between dies.

Discover the benefits of drop forging and how it works. Learn about the different materials used, applications, and industries that rely on this metal forming process. Find answers to your drop forging FAQs. Die forging or die forming is a manufacturing process, more precisely a forming process or solid forming process, and comes from the main group of forming. There it is assigned to the group of pressure forming together with rolling, free-forming, indenting and spinning. According to DIN 8583, it is a pressure forming process in which forming tools move against each other, the dies. Definition of forging Forging is defined as a metal working process that shape workpiece into desired dimensions by compressive forces applied through the use of dies and tools. Forging process is operated by hammering or pressing the metal. It is one of the oldest known metalworking processes with its origin about some thousands of years ago. At first,forging was

Metal forging is the process in which metals are formed and shaped using compressive forces. Learn about the different methods & processes.

What are the different types of dies used in tool and die manufacturing? In tool and die manufacturing, various types of dies are used, each suited for specific applications. Line dies perform single operations per press stroke, ideal for simple parts and prototypes.

In the realm of manufacturing, a die is a specialized tool used to shape, cut, or form materials—typically metals, plastics, or composites—into specific geometries through processes such offers excellent dimensional accuracy as stamping, forging, extrusion, or casting. Dies are fundamental to mass production, enabling the consistent replication of parts with high precision and efficiency. The term “die”

What is Forging? Forging is a process that involves shaping or forming materials, usually metal, through the application of heat and pressure. This process alters the material’s shape and structure, making it stronger and more durable. For continuous manufacturing, experts maintain regular steel material specifications with the forging company. Following the completion of the dies, steel billets will be removed from the material warehouse, chopped to the desired length, and heated in a medium-frequency furnace before forging. Step 3: The Actual Forging Process After the forging die design is completed, we will start the manufacturing process. In order to obtain high precision, the forging die must be processed by CNC. Therefore, in addition to the high material cost of forging dies, the processing

What are the 5 steps of the die making process?

Chapter Other Metal Shaping Processes 2001, Design for Manufacturing Corrado Poli 11.3.1 Types of Forging There are two broad categories of forging: open die and closed die. Closed-die forgings are also referred to as impression forgings since the forging dies partially enclose the workpiece material and restrict the flow of metal. Press forging uses a slow, continuous pressure or force to shape metal uniformly, instead of the impact used in drop forging. Upset forging Upset forging is a manufacturing process that increases the diameter of the metal by compressing its length. Crank presses, a special high-speed machine, are used in upset forging processes. This stage includes hammering, precision grinding, molding, compressing, extruding, bending, and upsetting, depending on the selected forging method and tooling design. The process may involve multiple passes through proprietary

Impression die forging is a metal forming process that involves the shaping of metal by the use of dies. The process uses a pair of dies that contain the required shape. The metal is placed between the dies and is subjected to high pressure, which causes it to flow and take the shape of the dies. This process shape metal uniformly instead of is widely used in the manufacturing industry for producing complex Understanding closed die forging Closed die forging, also known as impression die forging, is a manufacturing process that uses custom-shaped dies to create intricate, high-strength components with exceptional precision and uniformity.

The die-making process involves several precise steps to create high-quality, durable dies for manufacturing processes such as forging, stamping, or casting. Below are the five key steps in the die-ma Drop Forging Process General closed die drop forging process includes dies making, billet cutting, billet heating, drop forging, trimming, heat treatment, shot blasting, machining, surface treatment and inspection. Below we would like to introduce the drop forging process in detail.

Open die forging, also known as free forging, is a fundamental metalworking process used in manufacturing large, high-strength components. This method plays a crucial role in industries like aerospace, oil and gas, power generation, and more. In this article, we’ll break down what open die forging is, its key advantages, and the processes involved. 1. What is Open Die Forging?

What is Dies In Manufacturing

- Maria Rother Oldenburg | Kundenservice-Mitarbeiter mit E-Commerce-Erfahrung TZ

- Maria Theresia Bucquoi Aussprache In Französisch

- Marginale Importneigung • Definition

- Marine Phytoplankton Erfahrung: Vollständigste Lebensmittel?

- Mann Gesicht Clipart Bilder – Alter Mann Clipart Bilder

- Manolo Als Vorname: Bedeutung, Herkunft, Bewertung

- Mark Wahlberg: Liebevolle Geburtstagsgrüße An Seine Frau

- Manga One Punch Man 183 Online

- Management : Management Synonym

- Marblehead Lighthouse Preis , Marblehead Lighthouse, Ohio at Lighthousefriends.com