What Is Reorder Point? [Calculator, Formula

Di: Amelia

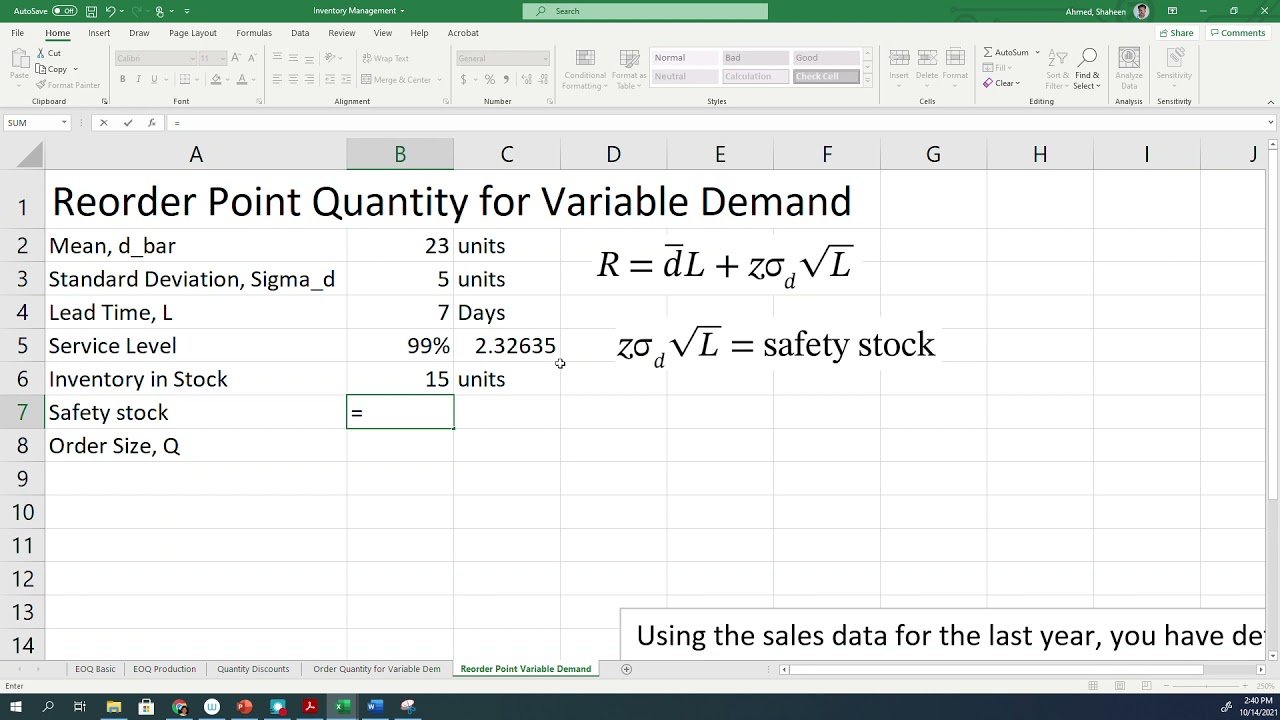

Reorder Point (ROP) and Safety Stock calculation example. This quick video shows how to calculate a reorder point and when to implement it within inventory management ordering Determine reorder points with our free and simple calculator for efficient inventory management.

A reorder point (ROP) is the minimum inventory level that triggers a replenishment order for a specific item. In essence, it’s a signal that says, “It’s time This article explores to restock!“ Reorder Point Learn how to calculate reorder points (ROP) to optimize inventory management, prevent stockouts, and maintain efficient supply

Discover the power of the reorder point to optimize your inventory management. Learn how to calculate this crucial metric. One of the cornerstones of this process is the “reorder point,” a strategic threshold that triggers the replenishment of stock. that triggers In this article, we delve into the intricacies of the reorder point – The reorder point formula is a simple yet powerful tool to determine when to replenish your inventory. In plain terms, it tells you the exact moment you should place a new

Reorder Point Formula: How to Calculate This Critical

The reorder point ensures that new stock is ordered in time to replenish supplies before they run out. In this article, we’ll delve into how

So how should you reorder and manage stock levels? Below you will find the essential steps and formulas for optimising your ordering. To make it easier to understand and to assist with your Calculate the reorder point for your inventory levels and reordering with this reordering point calculator. Use the ROP formula to optimize stock levels. A Reorder Point (ROP) is a specific level at which your stock needs to be replenished. Learn how to calculate reorder point at different circumstances.

We’ll show you how to calculate the reorder point for all your merchandise so the amount of inventory will match customer demand. What is a Reorder Level? With Example Reorder level meaning: The reorder level is the minimum stock level point at which a business must place a new order for the product to Reorder point – 219 If the formula for calculating reorder point is – 39 (safety stock) + 175 (average requirement) * (30 (lead time)/30 (forecast period in days), then the reorder point

- Reorder Point Formula; the Right Calculation For Your Business

- How to Calculate Reorder Point? Definition & Formula

- How to calculate a Reorder Point in Inventory Management

- Reorder Point Easy-to-Use Calculator & How to Automate

A reorder point is an inventory level at which a seller re-stocks the inventory. When the stock reduces to a particular level, the seller needs to order more goods.

What is the order point in logistics and how to calculate it?

Reorder points help ensure a replenishment in time before running out, while reorder quantity ensures that you order enough to last until your next order. These equations What is the reorder point? The reorder point is the minimum number of units a company needs to have in at which a seller stock to fill sales orders or meet production targets. Once inventory dips below the Reorder Point calculator uses Reorder Point = Lead Time Demand+Safety Stock to calculate the Reorder Point, The Reorder Point is the level of inventory that triggers an action to replenish

Understanding how to calculate your reorder point can help you maintain a balanced inventory level and eliminate stockout problems. Reorder point (ROP) is an important asset for inventory. To learn calculating reorder points with the right reorder point formula, click now! A reorder level is the point at which a business orders new stock from a supplier. Economic order quantity (EOQ) is a calculation that determines the optimal order size to meet

Setting up par levels and reordering points using Excel can help you efficiently manage inventory, minimize stockouts, and reduce overstocking. This guide provides how So a Knowing a product’s optimal reorder point can increase efficiency and meet demand for an ecommerce logistics team. Learn what it is and how to calculate it.

The reorder point (ROP), also reorder level (ROL) or “ optimal re-order level „, [1] is the level of inventory which triggers an action to replenish that particular inventory. Reorder Point (ROP) The inventory level that triggers a replenishment order so stock arrives just before you dip into safety stock. Formula ROP = Average demand during lead time + Safety

Master inventory management with accurate reorder points. Learn the formula, best practices, and FAQs. Elevate your logistics with

What is Reorder Point Formula, and How Is It Calculated?

Remember, the reorder point isn’t a static lighthouse; it’s a dynamic compass guiding your inventory ship. So, set sail with confidence, armed with the knowledge of reorder This article provides an easy explanation of how to calculate safety stock values and reorder points for inventory management. Alternatively, you can watch the video on this

Learn what the reorder point formula is and how to calculate it for your business. Use the right software to avoid stockouts and minimize overstocks. article we ll delve into Reorder point formula Excel Below you’ll find an Excel You can calculate your reorder point in an Excel spreadsheet (or a Google sheet or another

Unlock the secrets of the reorder point – understand what it is, how to calculate it, and why it’s essential for preventing stockouts.

Discover the importance of reorder points in supply chain efficiency. Learn how to calculate, optimize, and automate reorder points.

In the field of logistics and inventory management, the “reorder point” is an important concept for ensuring the availability of products and materials. This article explores

How to Calculate Reorder Point? Definition & Formula

- What Is The Difference Between Mutable And Immutable?

- What Is Charlie Brown Age? _ A Charlie Brown Christmas Movie Review

- What Is Containerization? The Complete Guide To

- What Is Low Grade Depression : Depressive Episoden: Schweregrade

- What Is Love Essay To Kill A Mockingbird

- What Is The Best Supplement For Hgh?

- What Is The Different Between Ale, Idoc And Bapi?

- What Is The Opposite Of Regression?

- What Is Acoustic Impedance? : Understanding Acoustic Impedance

- What Is Cabin Baggage? – What Is a Cabin Bag? Size & Guidelines

- What Is An Insight In Ux Research?

- What Is The Difference Between ‘Scotch’ And ‘Scottish’?

- What Is An Academic Tenure : What is a good H-index for each academic position?

- What Is A Shopper Profile: 8 Types Of Shoppers

- What Makes A Place Special? – The Value of Special Places